Lighting concept is turned into LED luminaire design at TOPLUMIN by a strong R&D team consist of experienced engineers in ID, structural, electrical, optical, and heat management.

We have set up a sophisticated development circle of LED luminaires. With the belief "design creates value", our R&D team is always prepared to develop custom-made LED fixtures to meet your specific lighting demand.

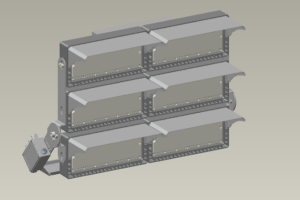

ID Design →

Requirements-oriented concept planning, professional software based design in appearance and structure.

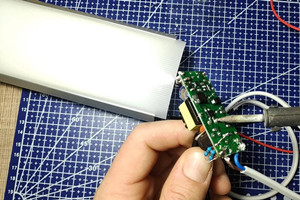

Prototype →

Prototype making by 3D printing. Check for assembly, wiring and function to conduct initial testing.

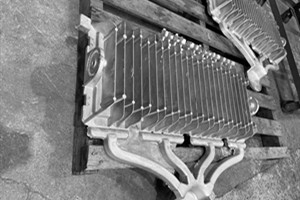

Revisions →

Design and make mold, then make improvements according to internal testing and feedback loop.

Trial Production →

Small production run to verify manufacture procedures, product electrical function and lighting performances.

Mass Production →

Bulk production of the verified product under strict quality control system, including IQC, IPQC, FQC, QA and more.

Lab Testing →

Random samples testing by accredited labs, making sure the performances data preset is met.

Batch Samples →

Compare with tested reference samples for every production run, ensuring stability of luminaire quality.

Certification →

As per customers' request, relevant certificates are applied and obtained, to be renewed in a timely manner.